Aviation

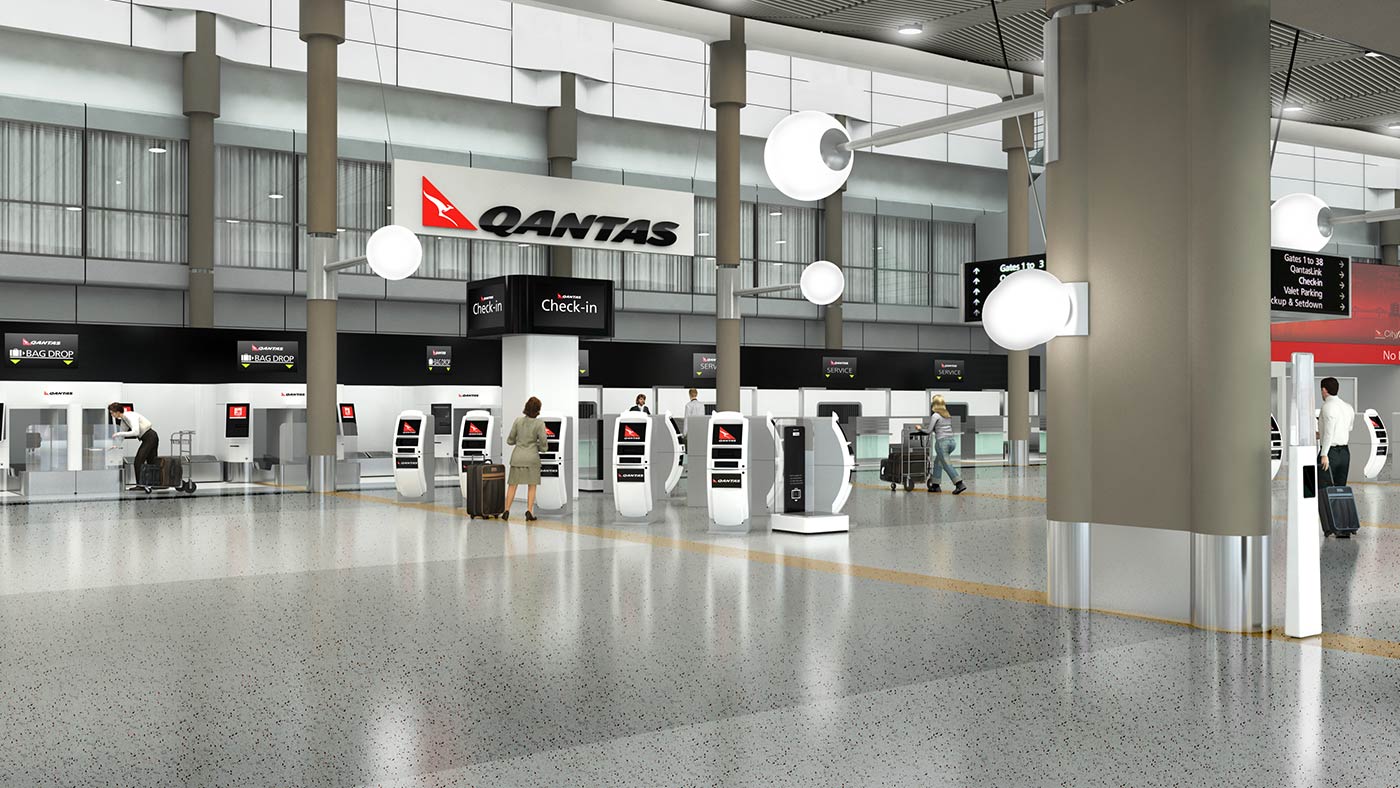

Brisbane Airports next generation check-in provides their customers with a smarter, faster check-in experience.

Project: Next Generation Check-In

Client: Qantas Airways Limited

Project Length: 11 Months

Budget: $13.5 million

Architect: Forrest Architects

Engaged as the principal contractor for the Qantas Next Generation Check-in project, CamPak constructed the new self-service system, enabling a faster check-in for passengers. Working closely with Forrest Architects, CamPak completed the $13.5 million project within an 11-month timeframe.

The redevelopment of Qantas Check-in procedures at the Domestic Terminal provided a substantial upgrade to facilities as well as an additional passenger security screening lane.

This development affected various Qantas departments including Ramp Services, Customer Services, Safety, Engineering and Port Control. Qantas required a full operational capacity that the construction was specifically managed to not to disrupt. To maintain operations within the Terminal, CamPak facilitated a regular working group committee with nominated Qantas department managers. In addition affected Qantas contractors responsible for operations and maintenance of baggage handling systems, security, valet, cleaning, IT and facilities management were notified and consulted to ensure Qantas operations and customer service were not affected.

The scope included alterations and expansion of the ‘back of house’ baggage make up system including a new carousel and CBS system, contained within a new bag hall structure and replacement of check-in counters and self help kiosks in the Departures Hall with new fixtures and fittings. It included provision of a new IT and communications room, an additional passenger screening lane, all ‘back of house’ tenancy alterations over level 1 & 2 of the terminal building, provision of temporary toilet facilities for Qantas staff and installation of secure storage facility for BHS spare parts.

CamPak respect your privacy and agree to keep your information safe

Over 25 years experience